Creating Green Eco-Friendly Erosion Control Solutions

DURABLE STOCKPILE CAPPING FOR EROSION CONTROL

HOW IT WORKS

DGR is formulated to coat and bond soil particles together by filling the

microscopic spaces between them to produce a strong but flexible seal. DGR has

undergone extensive development giving it class leading UV resistance, superior

bonding strength, expanded temperature range, increased flexibility and water

repellency.

USES AND BENEFITS OF DIRTGLUE

- Organic Based Polymer

- Erosion control

- embankment stabilization

- Stockpile capping

- Sediment control

- Dust control in non-traffic areas

- Hydromulching and seeding

- Environmentally safe and easy

PURPOSE BUILT SOIL STABILISER FOR ECO-SAFE EROSION CONTROL AND STOCKPILE CAPPING

DirtGlue® Regular Organic Based Polymer is a powerful, high-tech bonding agent specifically engineered to bond soil particles together. – DirtGlue® Regular penetrates the surface, binding with the soil to form a tough but flexible layer of protection. Combining superior film strength and adhesive properties, DirtGlue® Regular is the ideal solution for Stockpile capping, Hydroseeding, Stabilizing slopes and embankments. When hydroseeding, substituting DirtGlue® Regular in place of a traditional, old style tackifier increases germination rate, decreases germination time, and eliminates washouts, rilling and, erosion.

Over the years, the Polymer industry has had its name tarnished with the distribution of sub-par Polymers being sold and used as stabilisers. These Polymers are wildly inconsistent as they are often by-products of another process (paint manufacture, paper pulp etc.) which are then used as stabilisers. Due to the lack of UV stability, varying concentration of polymers and the polymers H20 re-absorption properties, all factors combine to give the end user a “Russian Roulette” style result and thus

“Polymers” for soil stabilization have in some instances developed a bad reputation…

DGR is a organic based acrylic polymer that has been manufactured with over 16 years’ worth of R&D and working alongside the US military / environmental industries. Over this time, GES in the U.S.A has been able to achieve outstanding results regarding this polymer’s stability and durability. DGR is UV stable and has had its water absorption rate lowered to less than 5%. What this means, is the Polymer will not break down and deteriorate in the sun and rain, therefore has incredible longevity in its

application.

.In Australia, DGR has been imported under a certification of “Inorganic chemical” which means it was not of a living origin. This is the most environmentally friendly product of its kind and it supports our GREEN solution methodology approach that GES and Green Track strongly believe is the way forward.

Most other polymer dust control products on the market use vinyl acetate copolymers. DirtGlue® Regular uses a proprietary polymer additive / mix (with no vinyl acetate copolymers) that offers greater UV stability and much better hydrophobicity. This insures each DirtGlue polymer application keeps working long after other products fail. This is an extremely important factor as there is no “one size fits all” application to projects. Each project needs to be approached on a case by case basis and an application method needs to be determined by the applicator. The customer needs to provide parameters and details about the surface’s use, weight it will bear and various other factors that need to be considered by the applicator before a process can be decided upon.

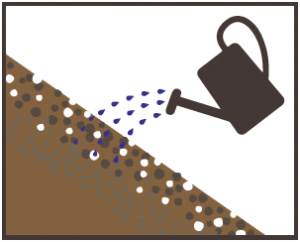

Embarkment Stabilisation & Stockpile Capping Application Guide.

Tools

SPRAY EQUIPMENT

DIRTGLUE REGULAR

WATER

Directions

1

Measure the area to be treated.

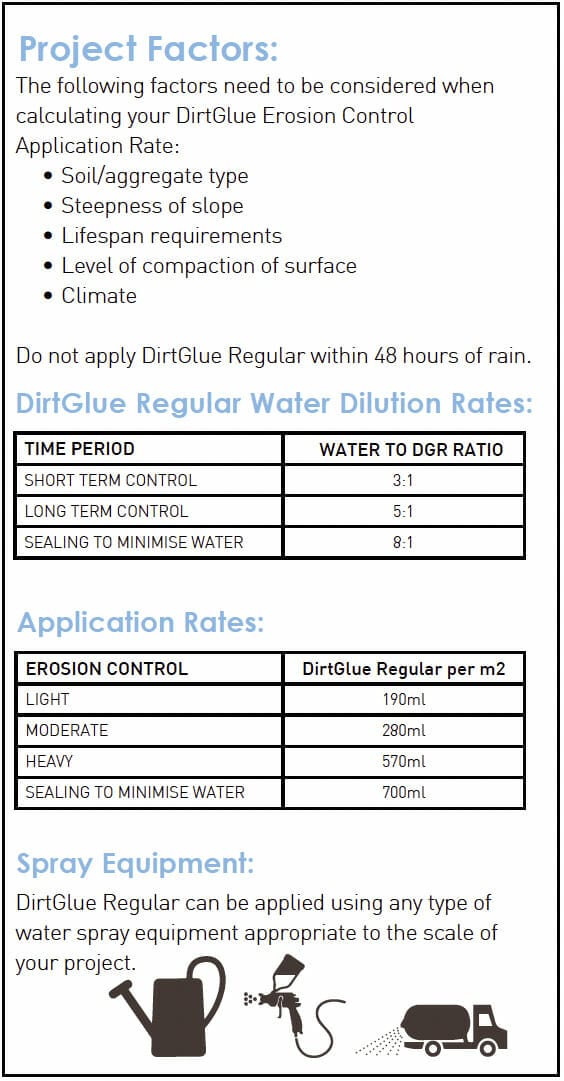

Determine the type of material to be treated (see project factors).

2

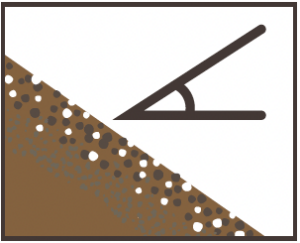

Determine the slope or grade of site.

3

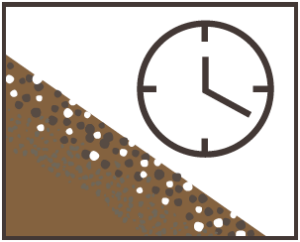

Determine the required lifespan and type of stabilisation required.

4

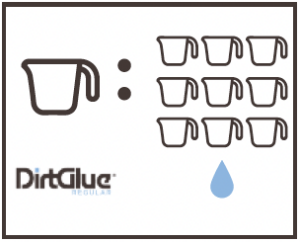

Calculate the required DirtGlue Regular application rate (see Application Rates).

Calculate the dilution rate required.

5

Skip to content

Skip to content