| Technical Characteristics | B4-P (piston) | B4-E (gear) |

|---|---|---|

| Tank capacity | 4 liters | 4 liters |

| Maximum pumping rate (Depending on adhesive type) | 29.3 kg/h pump 7 cc | 6 kg/h pump 2 cc/rev (50 rpm) |

| Maximum melting rate (Depending on adhesive type) | 6 kg/h | 6 kg/h |

| Number of outputs | 2 | 2 |

| Temperature range | 40 to 200 ºC | 40 to 200 ºC |

| Temperature control | RTD ±0.5 ºC (±1 ºF) | RTD ±0.5 ºC (±1 ºF) |

| Maximum working pressure | 81.6 bar (1183 psi) | 40 bar |

| Maximum installation power (at 230 VAC) | 3,680 W (16A) | 3,680 W (16A) |

| Electrical requirements | LN ~ 230V 50/60 Hz + PE | LN ~ 230V 50Hz + PE |

| External functions | Temperature ok output | Temperature ok output |

| External standby activation | External standby activation | |

| On/Off Motor pump Dimensions (LxAxH) | 600x320x354 mm | 600x320x354 mm |

| Weight | 36 kg | 38 kg |

| OPTIONS | ||

| Temperature range | 40 to 230 °C | 40 to 230 °C |

| Low level sensor | Capacitive (with warning light) | Capacitive (with warning light) |

| Granulate feeder | Yes | Yes |

| Automatic pressure control (VP200) | Yes | No |

| External connector pump activation | No | Yes |

Hotmelt Machine

Hotmelt Machine

Complete solutions for precise application of hot-melt adhesives in a wide variety of markets

Hotmelt Hose

| TECHNICAL FEATURES | STANDARD VERSION | ANTI-MOISTURE VERSION | |||

|---|---|---|---|---|---|

| Pt100 | Ni120 | NTC (R) | Pt100 | Ni120 | |

| Available diameters | 8, 13, 16 and 20 mm | 8 mm | 8 mm | ||

| Available lengths (enquire) | From 0.6 to 14 m | From 0.6 to 8 m | From 0.6 to 7.2 m | ||

| Max. operating temperature | Up to 230ºC | ||||

| Temperature sensors | RTD Pt100 or Ni120, NTC (R) (thermocouple J, enquire) | ||||

| Max. operating pressure | 120 (Ø8) / 100 (Ø13) / 70 (Ø16) / 65 (Ø20) bar at 200ºC | ||||

| Max. curvature radius | 200 (Ø8) / 300 (Ø13) / 350 (Ø16) / 400 (Ø20) mm | ||||

| Hydraulic connection | Female nut JIC 9/16′ (Ø8) 3/4′ (Ø13), 1 1/16′ (Ø16) M30x1.5 (Ø20) | Female nut M16x1.5 | Female nut JIC 9/16′ (Ø8) 3/4′ (Ø13), 1 1/16′ (Ø16) M30x1.5 (Ø20) | ||

| Electrical power supply | 200 or 230 V AC (control from the melting unit) | ||||

Manual Application

Easy to operate, lightweight, ‘Meler’manual applicators are highly robust and reliable mechanical components that guarantee a high level of precision and uniformity in the application of adhesive. Its complete 360º angle of rotation, allows in many applications a wide range of movement and flexibility.

| TECHNICAL SPECIFICATIONS | Manual Application |

|---|---|

| Heating time | 30 min. |

| Max. operating temperature | up to 230°C. |

| Temperature control | thermo resistance. |

| Temperature precision | ±0.5º C. |

| Hydraulic Pressure | >100 bar. |

| Voltage | 230 Vac, 50/60 Hz. |

| Electrical Consumption | 120W. |

| Method of activation | via trigger with safety catch. |

| Angle of rotation | 360º. |

| Weight | 750 grams. |

| Complete hose-applicator-nozzle kits are available, plus standard length hoses from 2,4 to 14 meters and different nozzles diameter. | |

Micro Precision

| TECHNICAL CHARACTERISTICS AND DIMENSIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. operating temperature | 200ºC (392ºF) | Pneumatic connection | quick disconnect; insulating tubes | ||||||||

| Temperature control | RTD ±0.5ºC (±1°F) | Operating speed (*) | 8.500 dots/ min | ||||||||

| Supply voltage | 230 VAC, 50 Hz | Minimum dot dimension (*) | 2.6 mm | ||||||||

| Heating power | 100 W | Fixation clamp | Ø12 mm rod | ||||||||

| Max. hydraulic pressure | 81,6 bar (1.183 psi) | Weight | 720 g, complete applicator (ready to use) | ||||||||

| Filter | 100 mesh (standard), integrated | (*) Depends on the type of adhesive, type of controller and solenoid valve. | |||||||||

| Air pressure supply | 6 bar; dry, clean, unlubricated | ||||||||||

| Solenoid valve voltage | 24 VDC | ||||||||||

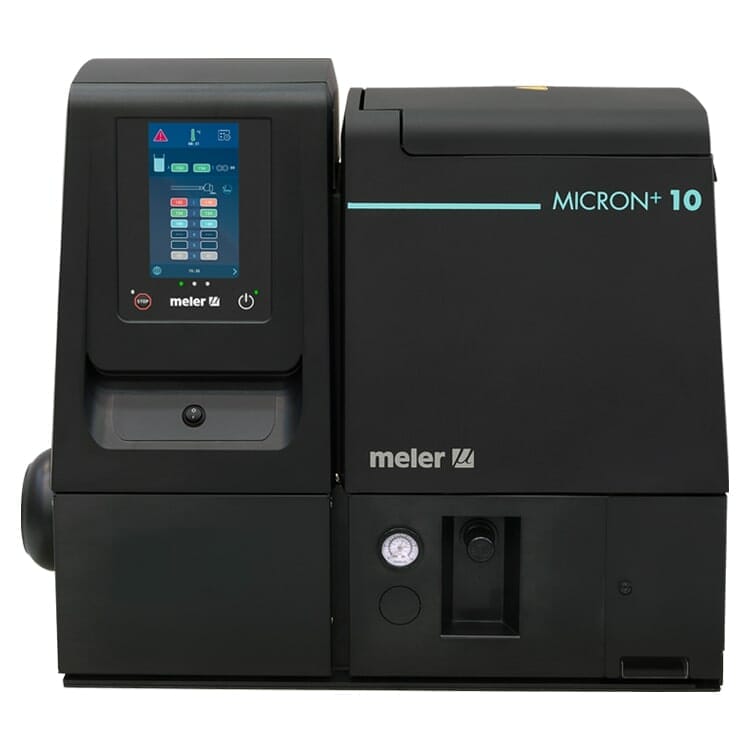

Micron +

| Technical Characteristics | Micron + |

|---|---|

| Melting rate* | from 9.0 to 30 kg/h. |

| Pumping capacity* | 29.3 kg/h for 7 cc pump (*); 66 kg/h for 19 cc (*) pump. |

| No. of outlets | 2,4 or 6 electrical outlets – 6 hydraulic outlets. |

| Range of temperatures | 0 to 200°C (32 to 392° F). |

| Temperature control | Pt100, Ni120 or NTC-R. |

| Maximum working pressure (up to 6 bars) | 81.6 bar (1183 psi). |

| External features | INPUTS: unit on/off, standby, activity control (input signal for auto standby/off), pump on-off, coms on-off, inhibition of electrical outlets.OUTPUTS: low adhesive level, pump on, standby, temperature OK, temperatures at set points, error, level error (warning light), feeding fault. |

| Electrical requirements | 1N ~ 230V 50/60Hz + PE or 3N ~ 400V 50/60Hz + PE. |

| Options | -Range of temperatures from 0 to 230°C (32 to 446°F). -VP-200 automatic pressure control.-Transformer base for 400 VAC without neutral (not available in 35 version).-Air intake filter,-Low level detector (not available in 230°C) or capacitive sensor with or without warning light.-Automatic adhesive feeder. |

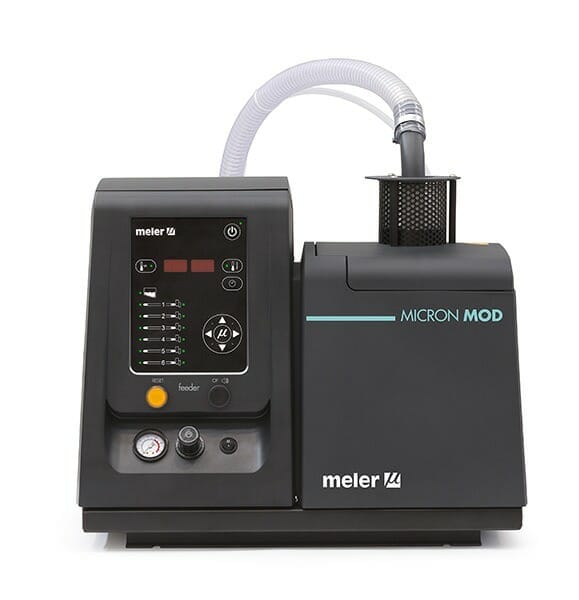

MICRON MOD

| TECHNICAL FEATURES | |

|---|---|

| Melting capacity”: | 15.5 kg/h |

| Pumping capacity”): | 29.3 kg/h, 7 cc pump |

| No. of outputs: | 2, 4 or 6 |

| Temperature range: | 40 to 200°C [104 to 392°F) |

| Temperature control: | RTD + 0,5°C [+ 1°F] |

| Maximum working pressure [6 bar): | 81.6 bar (1,183 psi) |

| Maximum installed power [ 230 VAC): | 4,820 W (2 outputs), 7,220 W [4 outputs) and 9,620 W [6 outputs) |

| External functions: | Temperature outputs OK, Input under maintenance, External output inhibition control. |

| Electrical requirements: | 1 ~ N/PE 400/230V 50/60 Hz or 3 ~ N/PE 400/230V 50/60 Hz |

| Dimensions (L x H x W) and Weight: | 587 x 377 x 577 y 47 kg (w/o automatic adhesive charging system]. |

| Options: | Automatic pressure control VP-200, Tower light. |

| * According to the type of adhesive. |

MICRON+ GEAR

| MICRON + 5 | MICRON + 10 | MICRON + 20 | MICRON + 35 | |

|---|---|---|---|---|

| MELTING RATE* | 9 kg/h | 13,5 kg/h | 19 kg/h | 30 kg/h |

| PUMPING RATE* | SIMPLE PUMP: 1, 2.5, 4, 8 cc/rev / DOUBLE PUMP: 2×0.93, 2×1.86, 2×3.71, 2×4.8 cc/rev | |||

| NUMBER OF OUTPUTS | 2,4 or 6 with one pump — 2 or 4 with two pumps | |||

| TEMPERATURE RANGE | 0 to 200 °C (32 to 392 °F) | |||

| TEMPERATURE CONTROL | Pt100, Ni120 or NTC-R | |||

| MAXIMUM WORKING PRESSURE (TO 6 BAR) | 90 bar (1.305 psi) | |||

| MAXIMUM INSTALLATION POWER | 1 simple pump/ 2 outputs | 1 simple pump/ 2 outputs | 1 simple pump/ 2 outputs | 1 simple pump/ 2 outputs |

| 1x 6,9KW/ 3 x 3,0KW | 1 x 8,0KW/ 3 x 4,0KW | 1 x 8, 5KW/ 3 x 4,5KW | 1x 10,0KW/ 3 x 4,3KW | |

| 1 simple pump / 4 outputs | 1 simple pump / 4 outputs | 1 simple pump / 4 outputs | 1 simple pump / 4 outputs | |

| 1x 10,5KW/ 3 x 4,0KW | 1x 11,6KW/ 3 x 4,0KW | 1x 12,1KW/ 3 x 4,5KW | 1x 13,5KW/ 3 x 6,1KW | |

| 1 simple pump / 4 outputs | 1 simple pump / 6 outputs | 1 simple pump / 6 outputs | 1 simple pump / 6 outputs | |

| 1x 14,2KW/ 3 x 5,8KW | 1x 15,2KW/ 3 x 5,8KW | 1x 15,6KW/ 3 x 5,8KW | 1x 17,2KW/ 3 x 7,9KW | |

| 2 simple pumps / 2 outputs | 2 simple pumps / 2 outputs | 2 simple pumps / 2 outputs | 2 simple pumps / 2 outputs | |

| 1 x 8,3KW/ 3 x 3,3KW | 1x 9,3KW/ 3 x 4,0KW | 1x 9,8KW/ 3 x 4,5KW | 1x 11,3KW/ 3 x 5,3KW | |

| 2 simple pumps / 4 outputs | 2 simple pumps / 4 outputs | 2 simple pumps / 4 outputs | 2 simple pumps / 4 outputs | |

| 1x 11,9KW/ 3 x 4,6KW | 1x 12,9KW/ 3 x 4,4KW | 1x 13,4KW/ 3 x 4,6KW | 1x 14,9KW/ 3 x 7,1/KW | |

| EXTERNAL FUNCTIONS | INPUTS: Unit on-off / standby / activity control / pumping on-off / communications on-off / shooting inhibition (with pattern controller integrated / electrical outputs inhibition | |||

| OUTPUTS: Adhesive level (nc) / pumping on / standby on / temperature zones ok / alarms on / unit ready / adhesive level (no) | ||||

| ELECTRICAL REQUERIMENTS | 1N ~ 230V 50/60Hz + PE / 3N ~ 400V 50/60Hz + PE / 3 ~ 230V 50/60Hz + PE | |||

| WORKPLACE TEMPERATURE | 0 to 40°C | |||

NC Series

| Technical Characteristics | NC Series | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Operating temperature | up to 230ºC (446ºF) | ||||||||||

| Max. working pressure | 90 bar (1.305 psi) | ||||||||||

| Max. pneumatic pressure | 6 bar; dry, clean, unlubricated | ||||||||||

| Operating speed (*) | up to 4.800 cycles/ minute | ||||||||||

| Temperature control | RTD ±0.5ºC (±1°F) (Ni120 or Pt100) | ||||||||||

| Supply voltage | 230 VAC, 50/60 Hz (from the melter unit) | ||||||||||

| Solenoid valve voltage | 24 VDC | ||||||||||

| (*) Depending on the type of adhesive | |||||||||||

| TECHNICAL FEATURES | PS20 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drum dimensions | Ø280 (inner diameter) x 400mm (up to 20 litre) | ||||||||

| Type of melting platen | Smooth | Axial platen | |||||||

| Melting rate (*) | 9-10 kg/h | 18-20 kg/h | |||||||

| Pumping capacity (*) | 1, 2.5, 4 and 8 cc/rev single pump | ||||||||

| 2×0.93, 2×1.86, 2×3.71 and 2×4.8 cc/rev double pump | |||||||||

| Number of pumps | 1 single pump or 1 double pump | ||||||||

| Number of hydraulic outputs | 2 per pump (3/4’ UNF thread) | ||||||||

| Number of electric outputs | 2 or 4 outputs (Standard version) | ||||||||

| Motor power | 0.250 kW | ||||||||

| Speed | 10-80 rpm (range 0-100 rpm) | ||||||||

| Temperature range | 40 to 200ºC | ||||||||

| Temperature control | RTD ±0,5ºC | ||||||||

| Maximum power pressure | 80 bar (1.160 psi) (recommended not exceed 70 bar) | ||||||||

| By- pass valve | Pneumatic (manual regulation) | ||||||||

| Maximum power supply | |||||||||

| 1 single pump/ 2 outputs | 5.000 W/ per phase | ||||||||

| 1 single double/ 4 outputs | 5.000 W/ per phase | ||||||||

| External functions | Temperature ok output, Empty drum output, Standby input, Motor start-stop external control, Motor speed external control | ||||||||

| Electrical requirements | 3N ~ 400V 50/60 Hz + PE | ||||||||

| Options | Tower light, Automatic air injection system for platen pulling out | ||||||||

| (*) According to adhesive type, platen type and working conditions | |||||||||

| TECHNICAL FEATURES | PS200 | |

|---|---|---|

| Drum dimensions | Ø571 (inner diameter) x 950mm (up to 200L) | |

| Type of melting platen | Smooth, axial platen or parallel platen | |

| Melting rate (*) | Up to 165 kg/h | |

| Pumping capacity (*) | 1, 2.5, 4, 8, 15, 20 and 30 cc/rev single pump | |

| 2×0.93, 2×1.86, 2×3.71 and 2×4.8 cc/rev double pump | ||

| Number of pumps | 1 single pump or 1 double pump | |

| 2 single pumps up to 8 cc/rev | ||

| Number of hydraulic outputs | 2 per pump (3/4’ UNF thread) | |

| Number of electric outputs | 2 or 4 outputs (Standard version) | |

| Motor power | 0.375, 0.55, 0.75, 1.1 kW depending on the type of pump | |

| Speed | 10-80 rpm (range 0-100 rpm) | |

| Temperature range | 40 to 200ºC | |

| Temperature control | RTD ±0,5ºC | |

| Maximum power pressure | 80 bar (1.160 psi) (recommended not exceed 70 bar) | |

| By- pass valve | Pneumatic (manual regulation) | |

| Maximum power supply | ||

| 1 single pump/ 2 outputs | 9.300 W/ per phase | |

| 1 single double/ 4 outputs | 10.500 W/ per phase | |

| External functions | Temperature ok output, Empty drum output, Standby input, Motor start-stop external control, Motor speed external control | |

| Electrical requirements | 3N ~ 400V 50/60 Hz + PE | |

| Options | Tower light, Automatic air injection system for platen pulling out | |

| (*) According to adhesive type, platen type and working conditions | ||

SDA Smart Dosing

| Technical Characteristics | SDA Smart Dosing |

|---|---|

| Precision Rate | 1% Tolerance (Max.) 1,5% Tolerance (for a CPK = 1,67) |

| Speed Lines | 150…300mm/s |

| Flow Rate (*) | Min. 6g/min – Max. 400g/min (* Depending on the pump 1cc, 2cc, 4cc) |

| Time response for bead sequences | Min. 0,9s for ±8 g/m change Min. 0,3s for ±1,6 g/m change |

| Applicator Pressure | 80 bar (1305-1160 psi) |

| Equipment Feeding Pressure | 30 bar (392-580 psi) |

| Max. Module Pneumatic Pressure | 6 bar; dry, clean, unlubricated |

| Applicator Temperature Control | (Pt100, Ni120) |

| Applicator Operating Temperature | Up to 200 ºC (392 º F) (see adhesive supplier recommendations) |

| Environmental Conditions | Ambient Temperature: 0… 40ºC Relative Humidity: 90% HR max. (at 30ºC) |

| Supply Voltage | 230 VAC, 50/60 Hz (from the melter unit) |

| Applicator Mass (approx.) | 4,5kg |

Swirl Application

| Technical Characteristics | Swirl Application |

|---|---|

| Max. operating temperature | up to 230 ºC (446 ºF) |

| Heating power | depending on the configuration used |

| Max. hydraulic pressure | 90 bar (1305 psi) |

| Max. pneumatic pressure | 6 bar; dry, clean and non-lubricated |

| Operating speed (*) | up to 4800 cycles/min |

| Temperature control | RTD ±0.5ºC (±1°F) (Ni120, Pt100 or NTC-R) |

| Power suppy voltage | 230 VAC, 50/60 Hz (from the melter unit) |

| Solenoid valve voltage | 24 VDC |

| (*) Depends on the type of adhesive. |